Radial compressors

Exhibitor

FIMA Maschinenbau GmbH

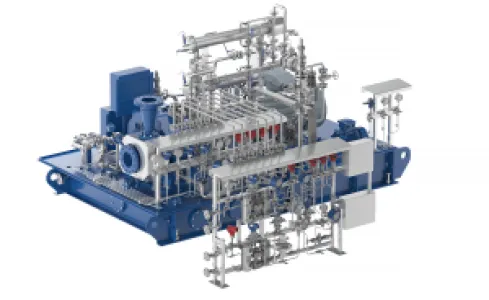

Our radial compressors include single- and multistage process gas compressors, process air compressors and mechanical vapour compressors. In the integral version, the impeller is directly mounted on the highspeed shaft. Alternative versions are fitted with intermediate bearings. FIMA is the acknowledged future champion of the world market leader in low-volume radial/ turbo compressors. This type of compressor is frequently implemented in chemical processing plants or refineries.

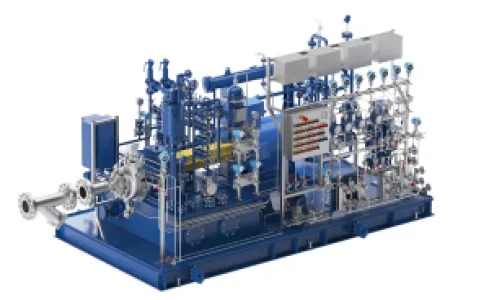

The plastic polyethylene (PE) is an extremely versatile product of the chemical industry. PE is used to make films of all kinds, beverage packaging, canisters, and even pipe jackets. The partially crystalline, nonpolar thermoplastic is divided up into different main types based on density. Through the selection of the polymerization conditions, the molecular weight, molecular weight distribution, kinetic chain length, and degree of polymerization are affected. Our F1 Series single-stage compressors are used in applications such as the licensed “Innovene G” process from Ineos for the production of linear low-density polyethylene (LLDPE). FIMA supplies the ejector boosters and the ethylene compressors for this process.

The plastic polyethylene (PE) is an extremely versatile product of the chemical industry. PE is used to make films of all kinds, beverage packaging, canisters, and even pipe jackets. The partially crystalline, nonpolar thermoplastic is divided up into different main types based on density. Through the selection of the polymerization conditions, the molecular weight, molecular weight distribution, kinetic chain length, and degree of polymerization are affected. Our F1 Series single-stage compressors are used in applications such as the licensed “Innovene G” process from Ineos for the production of linear low-density polyethylene (LLDPE). FIMA supplies the ejector boosters and the ethylene compressors for this process.

Compared with PE plastic, polypropylene (PP) is harder, is stronger, and can withstand higher thermal loads. Thanks to its special properties, PP has an extraordinarily wide range of applications. It is used in everything from vehicle interiors to food and cosmetics packaging, to pressure and drainage pipes. The licensed Novolen process from Lummus Novolen Technology for producing PP is just one example of the use of recycle gas compressors from FIMA. In general, these compressors return the unconverted propylene gas to the reactor. Smaller single-stage compressors are often used for homomer plants. So-called cascade compressors are also used in PP production. They are installed in the multistage variant.

Hydrogen is one of the most important chemical elements and is a component of nearly all organic compounds. In response to the challenges of the energy transition, numerous new hydrogen-based processes are emerging, thereby building on the already significant role of hydrogen in numerous chemical processes. One example is oxo synthesis, also known as hydroformylation. The large-scale process is used to produce aldehydes. Hydrogen serves as one of the starting products of the process. The resulting aldehydes are usually hydrogenated to form alcohols and are ultimately used as plasticizers, raw materials for laundry detergents and cleaning agents, or solvents. Because the process gas has a high hydrogen content, the material’s resistance to hydrogen embrittlement by the medium poses a special challenge.